Herstellung professioneller Schutzausrüstung

Herstellung professioneller Schutzausrüstung

EN 353-1:2014 (CE 0082)

Vertical fall arrest rail / ladder system

The SecuRail Vertical system is an efficient access solution for heights and depths. The shuttle (fall arrester) glides along the central rail and will block the fall of the user immediately while also dissipating the shock generated by the fall. Having a wide range of accessories the system can be configured to fit many types of structures and even existing access ladders.

|

Name |

|

|

A. |

Glide rail |

|

B. |

Shuttle - Gliding fall arrester |

|

C. |

Rung |

|

D. |

Special roof extension structure |

|

E. |

Support bracket |

Certification: EN 353-1:2014

Use: 1 person;

Materials: alluminium alloy (glide rail), stainless steel (rungs);

Inspections: at least once a year / immediately after the system has been involved in an incident;

Ladder height: not limited;

Installation:

- on a supporting structure (eg: mast, concrete wall, steel structure etc.);

- on an existing access ladder (onlly the fall arrest rail is installed in this case);

____________________________________________________________________________________

EN 353-1:2014 + A1:2017 (CE 0158)

Integrated fall arrest-ladder system

The Twinstop® system is an efficient acces solution for heights and depths. The shuttle (fall arrester) glides along the central rail and will block the fall of the user immediatelly while also dissipating the shock generated by the fall. Due to its simple and robust design it offers the same performances even in harsh working conditions (eg. cement, oil, icing) thus protecting the user for the entire climb / descent.

|

Name |

|

|

A. |

Ladder with integraded glide rail |

|

B. |

Shuttle - Gliding fall arrester |

|

C. |

Support bracket |

Certification: EN 353-1:2014 + A1:2017 Use: the system can be used by many users simultaneously, while keeping a safe distance from each other of minimum 3,36m! (Max. 1 person / Shuttle)

Materials: Stainless steel (shuttle), zinc plated steel (ladder-rail system)

Inspections: at least once a year / immediately after the system has been involved in an incident

Ladder height: not limited

____________________________________________________________________________________

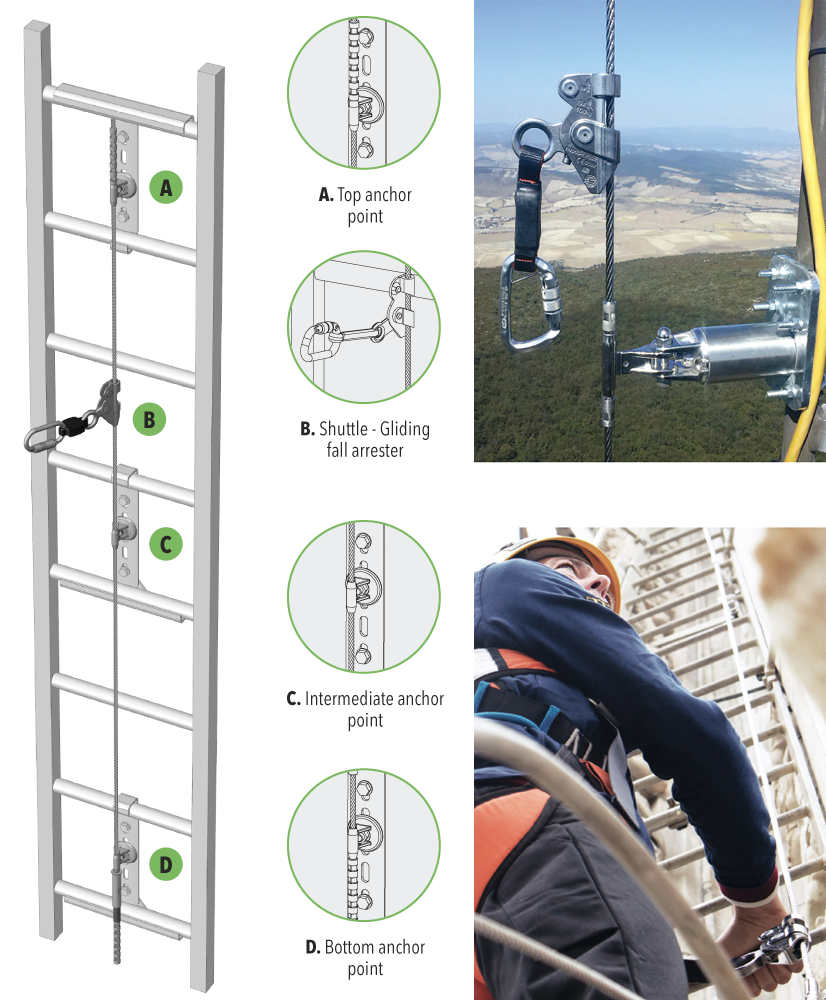

SecuRope® Vertical

EN 353-1:2014 (CE 0082)

Guided type fall arrester including a rigid anchor line

The SecuRope® Vertical anchor system is designed for permanent installation on ladders and offers reliable protection against falling, when the user is climbing the ladder as well for descending it. Its gliding shuttle "ZIP!" moves on a stainless steel cable and will instantly block a fall while the integrated energy absorber will limit the arising forces to a tolerable level.

Certification: EN 353-1:2014

Users: Max. 1 pers. (50 - 120 kg)

Cable: Ø8mm (Stainless steel AISI 316)

Expected service life: 10 years

Inspections: at least once a year / immediately after the system has been involved in an incident

Ladder height: not limited

Passing intermediate anchors: automatically

Installation posibilities:

- rung instalation

- side pole installation

____________________________________________________________________________________

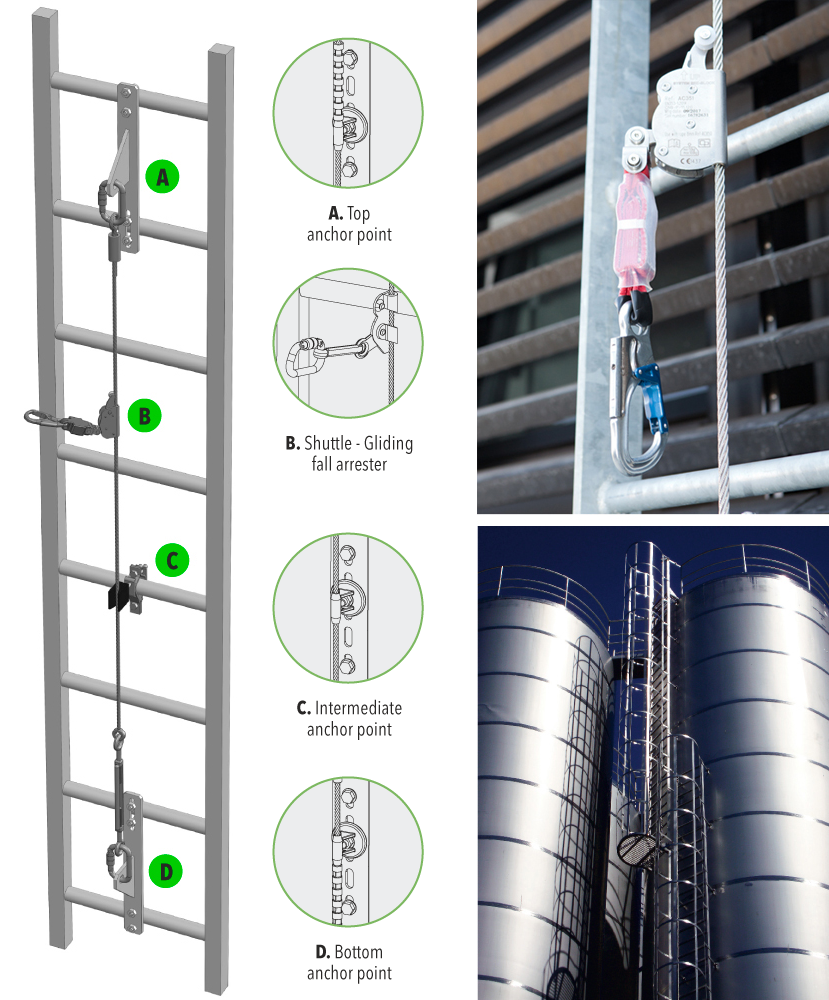

SKC

EN 353-1:2014 (CE 1437)

Guided type fall arrester including a rigid anchor line

The SKC vertical anchor system is designed to protect the user throughout the climbing or descending of a ladder. The anchor line consist of a stainless steel cable, intermediate anchors and terminal anchors. The gliding shuttle (fall arrester) will block the fall of the user immediatelly and will dissipate the shock generated by the fall, having an integrated energy absorber.

Certification: EN 353-1:2014

Users: Max. 1 pers. (50 - 100 kg)

Cable: Ø8mm (Stainless steel)

Expected service life: 10 years

Inspections: at least once a year / immediately after the system has been involved in an incident

Ladder height: not limited

Passing intermediate anchors: manually

Installation posibilities:

- rung instalation

*Note: These fall arrest systems are designed and configured to suit the needs for protection and to respect the spatial limitations existing at a particular workplace (the actual place of installation). Thus, prior to installation, it is necessary to do an on-site risk assessment and to carry out measurements.